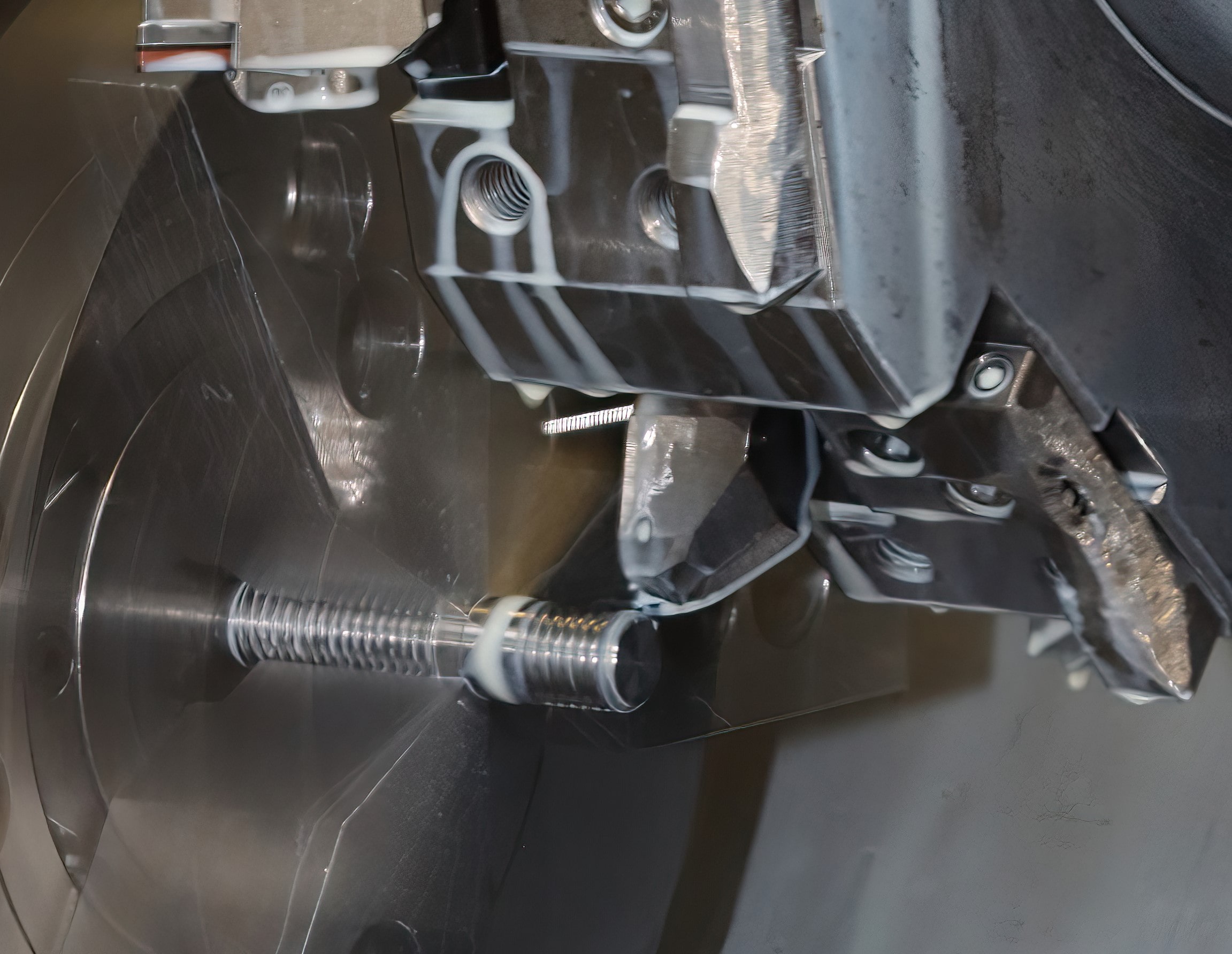

Our Specialty Manufacturing division is focused on the bespoke manufacture of Special Engineered Fasteners and Precision CNC Machined Parts to customer drawing or specification, in a wide range of materials, supported by any ancillary requirements for NDE, Mechanical Testing, and Surface Coatings.

SFC (Europe) combines traditional fastener engineering skills with the latest CNC manufacturing processes. Our internal manufacturing structure is split into dedicated production cells dependant upon product.

Please click here to review our current plant capacity.

Want to know more?

Would you like to discuss our products in more detail?